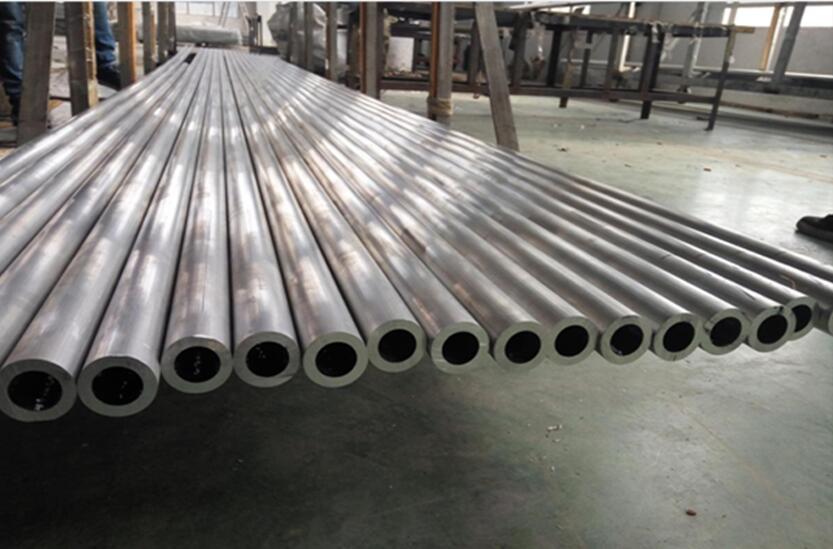

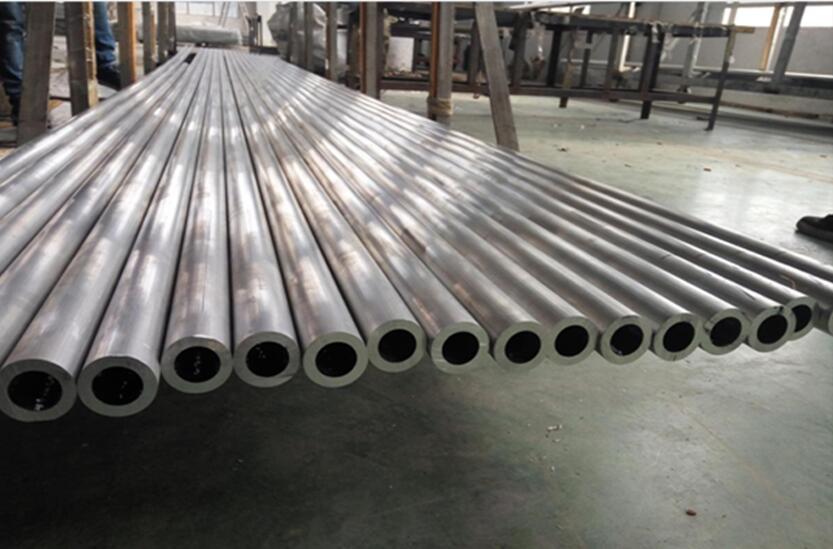

At the beginning of 2008, the southern part of the developing country suffered a major ice disaster that has not been encountered in 50 years, which caused great damage to the power supply system. The ice melting device requires matching electrical equipment, which must have a higher interception capacity and higher heat resistance. In order to meet the needs of the power market, our company has developed a high-strength heat-resistant wire in the high-current DC ice melting device With the use of extruded aluminum bus tube and its matching fittings, the product performance fully meets the requirements of power design and use after users' use, and has been well received by the power sector.

extruded aluminum bus tubes for electrical wires have good heat-resistant properties, and have high strength at higher operating temperatures (150°C ~ 200°C). It can be heated to 250°C for one hour and can still be cooled after natural cooling. Maintaining high mechanical properties, tensile strength can still maintain 80% of normal temperature, and strong icing resistance.

The main performance of

extruded aluminum bus tubes for electrical wires is reflected in:

1)

extruded aluminum bus tubes for electrical wires use a series of advanced technologies such as domestic advanced hot-top casting seamless tubes, with smooth surface, high dimensional accuracy, high tensile strength, and resistance to discharge and deformation;

2) The product adopts the rare earth, heat-resistant aluminum alloy material developed by the company, which has excellent processing, welding, electrical conductivity and heat resistance. The product has been appraised by the science and technology department and has reached the international advanced level;

3) Good convection heat dissipation conditions, low temperature rise, low loss, strong conductivity and large current carrying capacity;

4) High heat resistance, can increase the working temperature of the tube bus (working temperature reaches 150℃-200℃), the conductor has high mechanical strength at high temperature, and improves the safety and reliability of the power transmission and transformation system